.jpg)

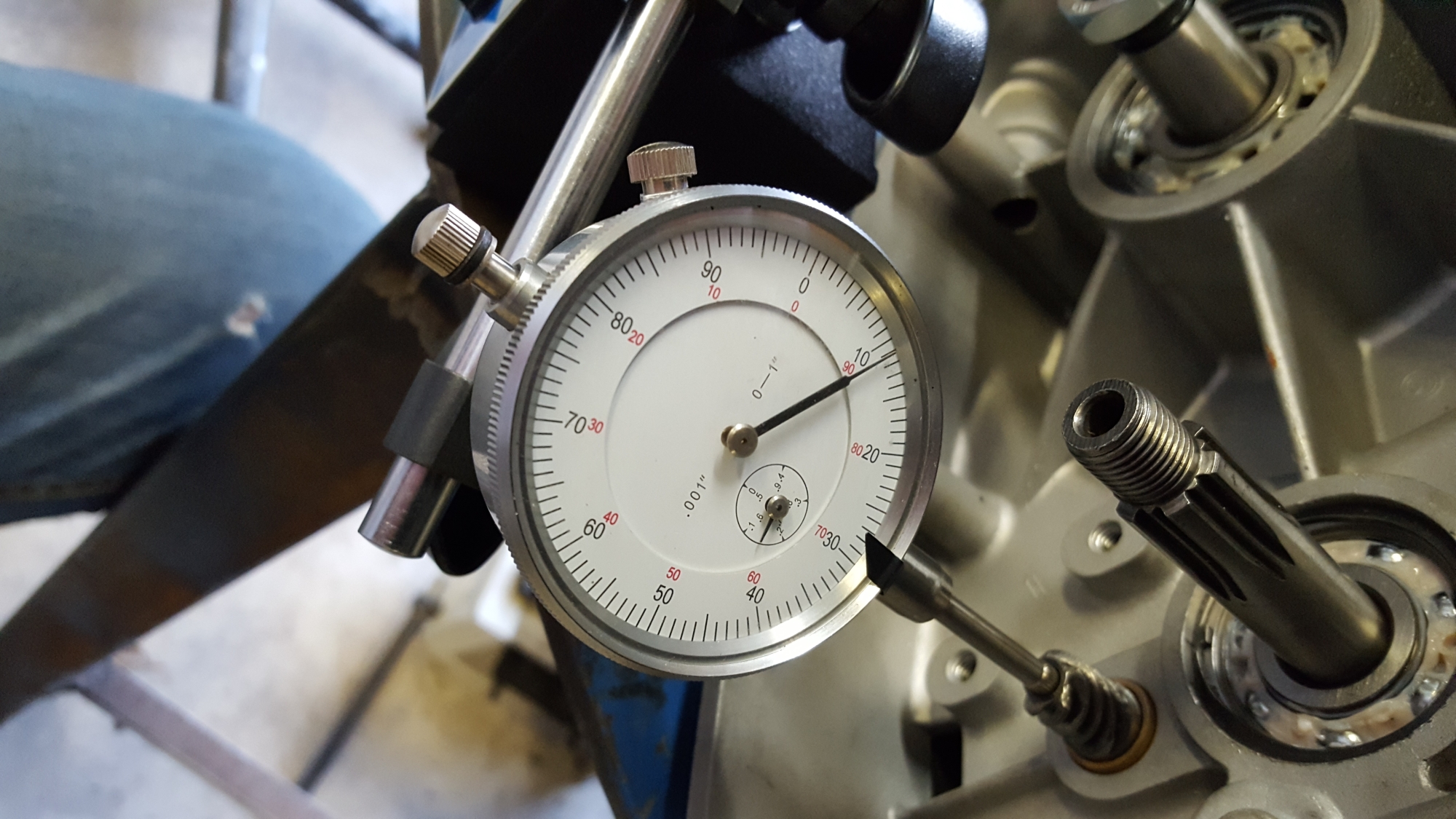

1. Centering the crank

As we have rebuilt a new crank around the old flywheel and are using new crankcase halves and new bearings, it is necessary to shim the crank to give it the appropriate endfloat and ensure it is centered. To do this we checked the old main bearings against the new and found them to be exactly the same size (width). We then spun the old bearings up on the lathe and relieved the centres with emery paper so they slipped on and off the crankshaft easily. We pressed the old bearings into the crankcases and bolted up the crankcase halves with the flywheel inside. The old bearings allowed the crankshaft to be pushed backwards and forwards to measure endfloat and the centre point. The CZ 175 flywheels run extremely close to the crankcase in the mouth and clearance between each side can be measured with a feeler gauge. By this method we inserted shims to centre the flywheel and left enough for a reasonable degree of endfloat. Once we had balanced each side we set the endfloat at .0008". Then it was simply a matter of popping out the old bearings, in with the new and double-checking the clearances with the feeler gauge. Perfect.

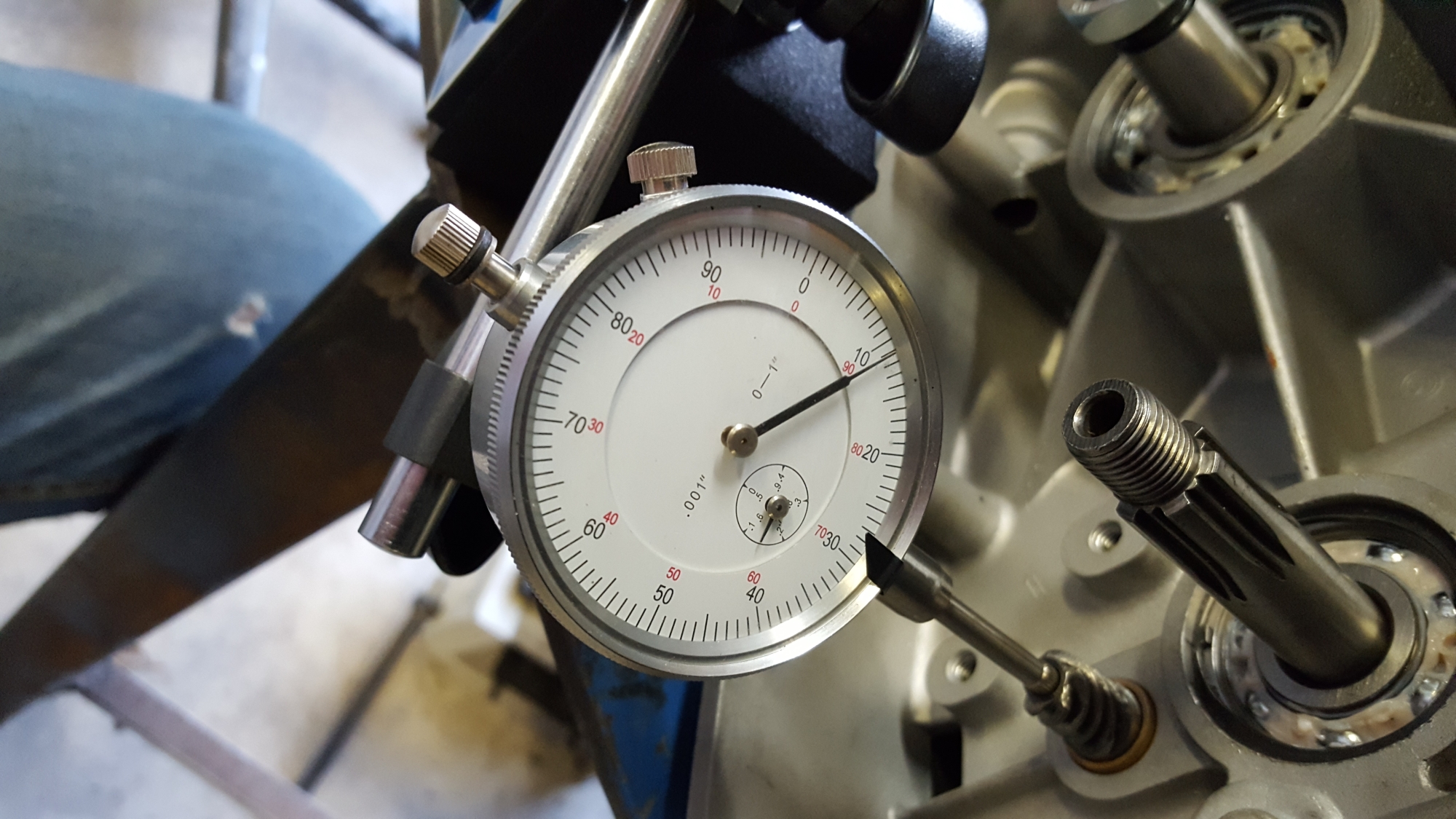

2.Gearbox layshaft

On many Jawa/CZ motorcycles the gearbox layshaft must be shimmed to give 0.3mm endfloat. Easy to do with the right instruments and it ensures positive gear-changing.

.jpg)

3. The clutch side

The clutch side was remarkably easy to assemble. Despite new clutch plates and new springs we were able to insert the little "dumbbells" with almost no effort. Granted it took two people - you really need four hands - but next time we'll make the special tool detailed in the Jawachat files to make it a one person job.

.jpg)

4. The Slick-Shift

Many Jawa/CZ bikes are fitted with an "Auto-Clutch" which is an ingenious system whereby the clutch rod is pushed in when the gear lever is pressed. Hence the hand clutch becomes unnecessary. We are told that, with a little practice and thanks to the (much maligned) long throw gear shift, the auto-clutch can even be used to move off from a standing start. Hence a broken clutch cable will not leave the bike stranded out on the road. The actual mechanism is simple and was easy to assemble.

.jpg)

5. Barrel paint

The barrel was stripped by the engineer and we have painted it in gloss high temperature barrel paint. Available at your local auto parts store it really looks better than rusty cast iron!

.jpg)

6. The oil pump

We had already been disappointed by the discovery of the lack of the oil pump drive on the ends of the new crankshaft but our spirits were lifted when we took the old oil pump out of the parts box and looked at it closely. The oil pump gallery is subject to water seeping in and over the years the pump had been immersed in water and simply rotted through. It would NEVER have worked. No chance. On the list goes a new crank and a new oil pump. Frankly unlikely, premix is fine.

.jpg)

7. Old Jikov carby

The old Jikov carby looked as if it had seen better days. We were not sure if it could be refurbished but we ordered a carby kit from Jawashop, stripped down the carb and had it bead blasted.

.jpg)

8. Refurbished Jikov carby

The carby kit arrived with literally everything you need to refurbish a carburettor. Every spring, screw, jet and washer was in the pack so after a gentle bead blast the carby was very, very carefully cleaned and reassembled. It's like new.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)